- Metalwërks

Upgrading Through Recladding: What’s Possible with Metal

Upgrading Through Recladding: What’s Possible with Metal

Why Recladding is a Smart Investment

So much about the building products industry seems to focus on novelty. New buildings get the shiniest facades, most eye-popping designs, and products that push the very boundaries of architectural design. The challenge is that over time, what was once a novel, compelling look can age and become outdated. Eventually, it can feel as if older buildings become less alluring even if they had a nuanced design at their inception.

In today’s uncertain economy, the reclad or “re-skin” market is poised to again assert itself in dominant fashion. In doing so, it affords designers and building owners with a way to give an older building new life, often on a more manageable budget.

Revitalization efforts on a dated façade can be smaller in scale by incorporating new features such as screenwalls or canopies while still delivering a much-needed facelift. For a larger-scale renovation, an updated design will need to conform to contemporary building codes that may not have been in place when the original building was erected. Most regions have adopted codes that require more strict total wall R-values for thermal resistance. Fire safety regulations have also been made more stringent.

Despite these new standards, older buildings can update their aesthetics and performance in a far easier process than many imagine while remaining visually compelling with the latest architectural creativity.

Solid metal panels play a vital, growing role in this construction paradigm. Solid aluminum in particular is lightweight and capable of providing large formats or flexible undulations on any façade without significantly increasing the dead load of the new façade skin onto the existing structure. In fact, it could be even lighter than its predecessor when selected to replace masonry or curtain walls.

Looking Beneath the Surface

In uncertain economic times, recladding an existing facility is often a more cost-competitive way to achieve an updated look for a building that is outdated. When compared to building a new facility, the cost differential can be substantial. At the same time, reskinning or recladding a structure provides ample opportunity to enhance the performance of the building envelope, thereby enabling the finished product to meet ever-expanding building codes for performance and energy efficiency.

In most cases, such a project involves the complete removal of the exterior skin and secondary supports all the way to the underlying structure. Alternatively, buildings can be re-skinned by removing only the outer veneer layers and using the old elements as a substrate for the new layer(s). In either case, designers must pay special attention to the structural and thermal performance improvements.

Such cases are where design assist services are most valuable. This hands-on collaboration with a cladding professional affords property owners an opportunity to work with cladding experts to see what upgrades are available for their specific application.

For example, if a solid metal plate exterior is what is preferred for an extended color palette, flexibility, and durability, the design-assist process taps into a manufacturer’s expertise. This one-on-one process is a reliable way to stay in tune with the latest aesthetics and what requirements will be needed to meet or exceed contemporary code mandates.

From there, buildings will receive the sought-after facelift and likely some enhanced energy benefits that equate to future cost savings.

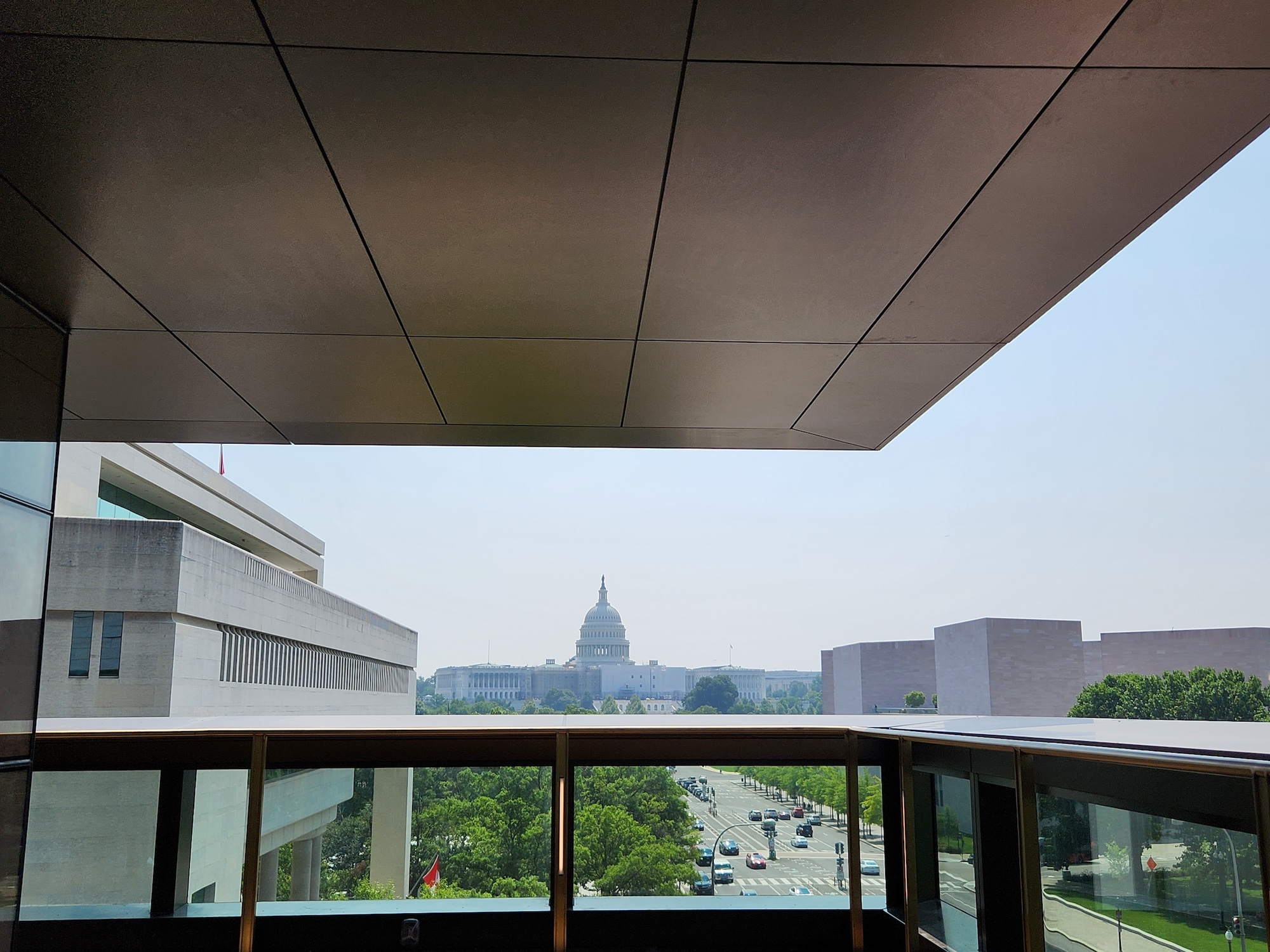

Consider the example of Courthouse Square in Wilmington, DE. Opened in 1984, the building’s era-locked exterior began to age as time progressed. Eventually, it was time for an update. What followed was a significant exterior renovation that brought the structure’s appearance into the 21st century. In total, 15,000 sq. ft. of Metalwërks’ Omniplate™ 1500 metal plate was installed to replace the aged, opaque spandrel panels and offer a refreshed look for tenants and the neighborhood.

Courthouse Square’s update was not just skin-deep. Thanks to clever engineering, the building’s elegant metal plate exterior also served as the building envelope’s primary weather barrier. The result is a far more modern look and one that is far more resilient against the elements than the previous cladding. Though this project specified metal plate with clean lines and gentle bends, the Omniplate cladding also offered freedom of form for curves or other complex, three-dimensional looks. When specified, these advantages can significantly augment a property’s eye-catching curb appeal.

Retrofit While Staying up to Code

States such as New York and California already have robust and established building codes. Because these areas tend to be more progressive in codifying industry innovations or worthwhile trends seen abroad, they often pioneer building code changes for the rest of the United States.

Because these states are early adopters of nuanced techniques, products, and methods, construction projects in these geographies often forecast trends to come for other cities and states.

For example, New York City has modified its building code, pivoting toward an emphasis on durability. Chapter 14, which addresses requirements for exterior walls of buildings, lays out minimum durability, material performance, and dire resistance standards for buildings. Thermal efficiency has also been made a priority here, as covered in 1403.7, with thermal and condensation resistance being mandated to meet the New York City Energy Conservation Code requirements.

Translucent, glass-heavy facades are transitioning into more energy-efficient options with opaque surfaces. Such options still allow for an elegant aesthetic while also adding more insulation and overall protection. This is also the case for large curtain wall buildings that transition to window-wall facades.

Because of these code changes, existing buildings are being reclad with newer facades that fall in line with the updated guidelines. These details are particularly vital when considering potential compliance with codes like NFPA 285.

Options for all Economic Conditions

Even in a bearish economy, upgrade options exist for property owners and developers that may not otherwise have been considered.

With purse strings drawn tight, developers can find an affordable investment alternative in recladding existing properties. This is especially prudent considering the far higher cost of new construction, particularly in times of economic uncertainty.

In scenarios like this, investments in an existing real estate portfolio show a commitment to building upkeep and a willingness to remain competitive with the aesthetic offerings of the property’s established market. Such is particularly the case for commercial and residential landlords.

Updated materials on buildings can lead to other less tangible rewards such as far safer buildings, energy-saving materials, enhanced resistance to severe weather, or even LEED certification, if so desired.

Modern Looks for All Buildings

New or old, it’s worthwhile for a building’s exterior to offer the latest benefits in thermal efficiency, weather resilience, and of course, looks. The glimmer of new construction can certainly be alluring. At the same time, there are plenty of options to upgrade an established property with a dated design.

In all economic conditions, recladding is a smart, budget-conscious way for properties to deliver looks that dazzle. Solid metal panels play a vital role in this endeavor, delivering adaptable material that is durable, visually stunning, and energy efficient.