- Metalwërks

- Products

Arcwall™ Ship Lap

Product Comparison Chart

Scroll »

| Rainscreen Wall Systems | Barrier Wall Systems | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sculpted 3D* Minimal |

Sculpted 3D* Ribbon |

Sculpted 3D* Parametric |

Arcwall Standard |

Arcwall Advanced |

Arcwall Spline Shiplap |

Econowall | Omniplate 1500 |

Omniplate 2510 |

||

| Performance | Drained and Back-Ventillated Rainscreen |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | × | × |

| AMMA Pressure- Equalized Rainscreen |

× | × | × | × | ✔ | × | × | × | × | |

| Dry-Sealed Barrier Wall |

× | × | × | × | × | × | × | × | ✔ | |

| Wet-Sealed Barrier Wall |

× | × | × | × | × | × | × | ✔ | × | |

| Materials | Coated Aluminum |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Stainless Steel |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Zinc | ✔ | ✔ | ✔ | × | × | × | ✔ | × | × | |

| Panel Forms | Flat | × | × | × | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Curved | × | × | × | ✔ | ✔ | ✔ | × | ✔ | ✔ | |

| 3D | ✔ | ✔ | ✔ | ✔ | ✔ | × | ✔ | ✔ | × | |

| Panel Returns | Formed | ✔ | ✔ | ✔ | ✔ | ✔ | × | ✔ | ✔ | × |

| Flat | × | × | × | × | × | ✔ | × | × | ✔ | |

| Back-Scored | ✔ | ✔ | ✔ | ✔ | ✔ | × | × | ✔ | × | |

| Panel Dimensions (inches) |

Length | 24-160" | 48-160" | 24-160" | 12-160" | 12-160" | 12-240" | 12-160" | 12-160" | 12-240" |

| Width | 24-66" | 24-48" | 24-50" | 12-65" | 12-65" | 12-72" | 6-36" | 12-65" | 12-72" | |

| Depth | Varies | Varies | Varies | 1.75" | 3.75" | 2", 2.25", 2.75" | 1.5" | 1.75" | 2.25" | |

| Panel Orientation | Horizontal | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Vertical | ✔ | × | ✔ | ✔ | × | ✔ | ✔ | ✔ | × | |

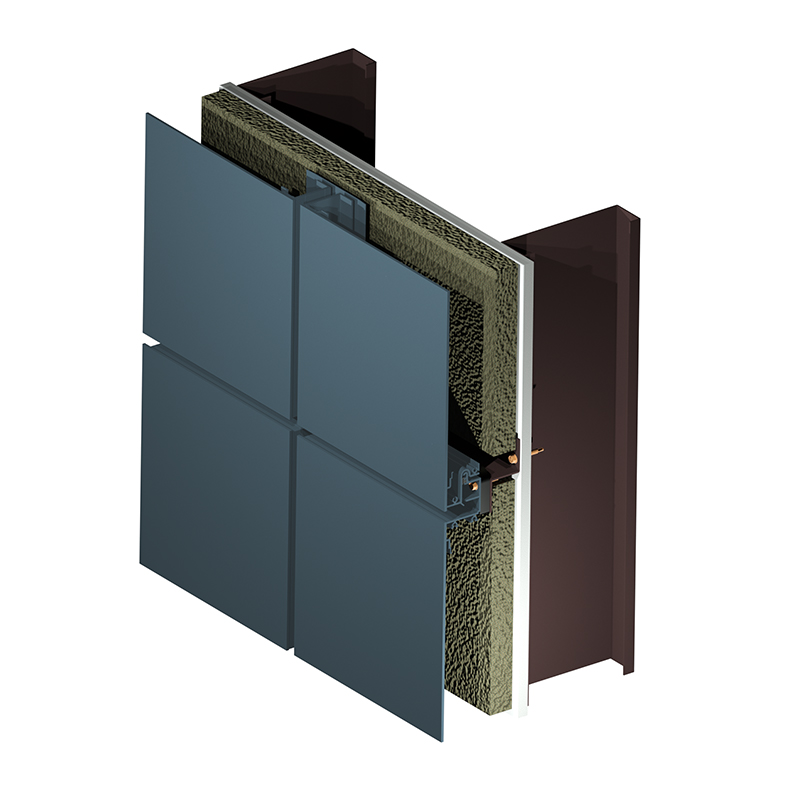

Efficiency and fascinating free-floating effects are hallmarks of Metalwërks® Arcwall wall systems.

With Arcwall, the cut edges of the faceplate material are the panels’ edges, a capability in metal you can only achieve with plate. When Arcwall attachment hardware is concealed from view, architects achieve a fascinating floating panel effect.

The fabrication efficiency of Arcwall, combined with Metalwërks simplified panel attachment options that speed installation, make for a highly competitive, high-end rainscreen wall system. Arcwall panels are factory assembled with a flat plate facing structurally adhered to an extruded aluminum panel frame and may be flat or curved. Two-dimensional geometries of panel facings are virtually limitless and panels may be installed in any direction. Joint sizes can be variable and reveals can use a complimentary or contrasting finish. There are three primary design methods.

All Arcwall systems install with concealed fasteners over continuous masonry, concrete, or as the outer cladding in a wall assembly that incorporates continuous insulation and a suitable air and water barrier. Solid metal panels are particularly useful where metal panels are used in pedestrian areas due to superior impact performance compared to other composite metal panel cladding products.

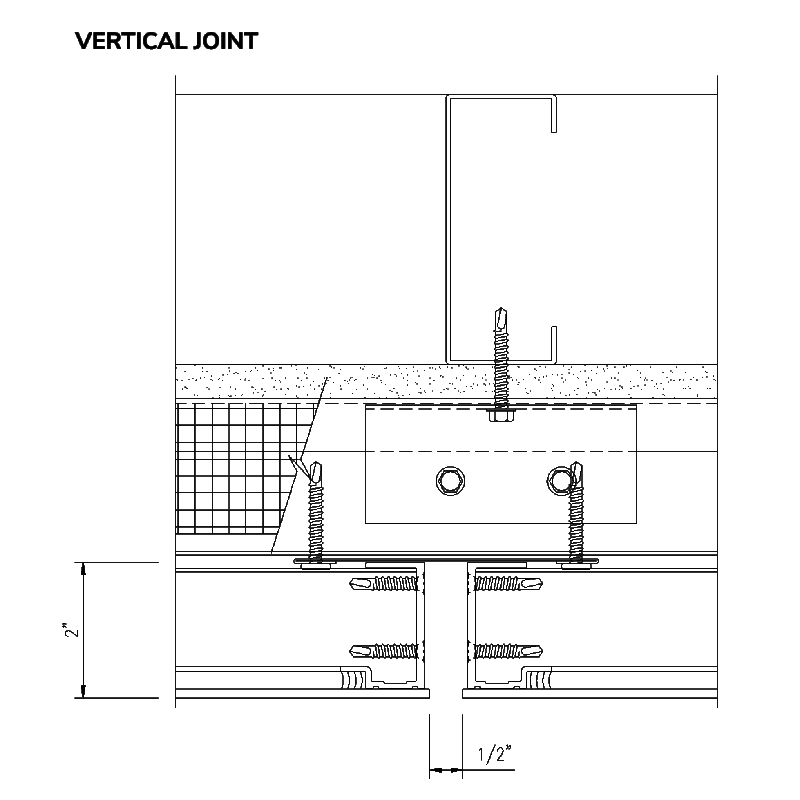

Arcwall Ship Lap Details

Arcwall Ship Lap Design Options

Arcwall Ship Lap Metal Substrate and Finish Options

Panel Sizes

Widths: 12” (305 mm) to 72” (1,829 mm)*

Lengths: 12” (305 mm) to 240” (6,096 mm)*

Depth: 2.25" (57.15 mm)

* Maximum panel size depends upon plate material, gauge, finish, and geometry.

Panel Weight Range

(dependent upon gauge and geometry)

Aluminum: 2.62 - 4.42lbs./ft2

Stainless Steel: 6.32lbs./ft2

Ranges provided for clarification.

Consult with Metalwërks for further options.

Accessories

Flashing: Formed aluminum or stainless steel sheet metal as required for base or penetration conditions produced from matching material/finish as panels

Coping: May be produced with the same material as the wall panel system

Furring Channels: As required for proper mounting of panels

Perforated Panels and Louvered Vents: For accents, screening or ventilation.

Consult with Metalwërks for options.

Fasteners: Type 304 stainless steel or cadmium-plated as recommended

Shims: High impact thermally-broken plastic shims to maintain co-planar surfaces

Warranty

Material & Workmanship: 1-year standard, with 2- or 5-year options

Finish Integrity: 10-year standard, up to 20-year