- Metalwërks

- Products

Canopy Cladding

Product Comparison Chart

Scroll »

| Rainscreen Wall Systems | Barrier Wall Systems | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sculpted 3D* Minimal |

Sculpted 3D* Ribbon |

Sculpted 3D* Parametric |

Arcwall Standard |

Arcwall Advanced |

Arcwall Spline Shiplap |

Econowall | Omniplate 1500 |

Omniplate 2510 |

||

| Performance | Drained and Back-Ventillated Rainscreen |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | × | × |

| AMMA Pressure- Equalized Rainscreen |

× | × | × | × | ✔ | × | × | × | × | |

| Dry-Sealed Barrier Wall |

× | × | × | × | × | × | × | × | ✔ | |

| Wet-Sealed Barrier Wall |

× | × | × | × | × | × | × | ✔ | × | |

| Materials | Coated Aluminum |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Stainless Steel |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Zinc | ✔ | ✔ | ✔ | × | × | × | ✔ | × | × | |

| Panel Forms | Flat | × | × | × | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Curved | × | × | × | ✔ | ✔ | ✔ | × | ✔ | ✔ | |

| 3D | ✔ | ✔ | ✔ | ✔ | ✔ | × | ✔ | ✔ | × | |

| Panel Returns | Formed | ✔ | ✔ | ✔ | ✔ | ✔ | × | ✔ | ✔ | × |

| Flat | × | × | × | × | × | ✔ | × | × | ✔ | |

| Back-Scored | ✔ | ✔ | ✔ | ✔ | ✔ | × | × | ✔ | × | |

| Panel Dimensions (inches) |

Length | 24-160" | 48-160" | 24-160" | 12-160" | 12-160" | 12-240" | 12-160" | 12-160" | 12-240" |

| Width | 24-66" | 24-48" | 24-50" | 12-65" | 12-65" | 12-72" | 6-36" | 12-65" | 12-72" | |

| Depth | Varies | Varies | Varies | 1.75" | 3.75" | 2", 2.25", 2.75" | 1.5" | 1.75" | 2.25" | |

| Panel Orientation | Horizontal | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Vertical | ✔ | × | ✔ | ✔ | × | ✔ | ✔ | ✔ | × | |

* Patent Pending

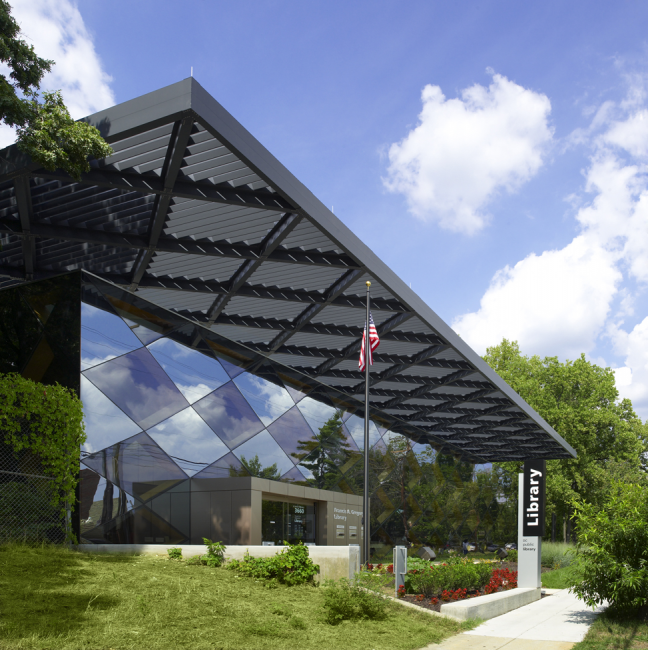

To provide an architecturally cohesive appearance and performance, Metalwërks® Canopy Cladding is often formed from the same metal plate material as a building’s Metalwërks plate wall system.

Canopy Cladding can be created from flat, curved, or 3D panels. Also, formed metals, architectural grilles, lighting, speaker grilles and other elements are easily integrated.

Uses of Canopy Cladding

- Entrance canopies and vestibules.

- Projecting features for shading or architectural treatment at prominent locations.

- Incorporate lighting, glazing and HVAC features.

- Cornice features as shading devices to reduce glare and solar heat gain.

- Porte Cocheres, Trellis, and larger entry elements require multiple products from a single source.

- All

Features and Benefits of Canopy Cladding

Metal Substrate and Finish Options

Panel Sizes

Widths: 12” (305 mm) to 65” (1,651 mm)*

Lengths: 12” (305 mm) to 160” (4,064 mm)*

Depth: Varies

* Maximum panel size depends upon plate material, gauge, finish, and geometry

Panel Weight Range

(dependent upon gauge and geometry)

Consult with Metalwërks for options.

Warranty

Material & Workmanship: 1-year standard, with 2- or 5- year options

Finish Integrity: 10-year standard and up to 20-year for coated aluminum

* Patent Pending