- Metalwërks

- Products

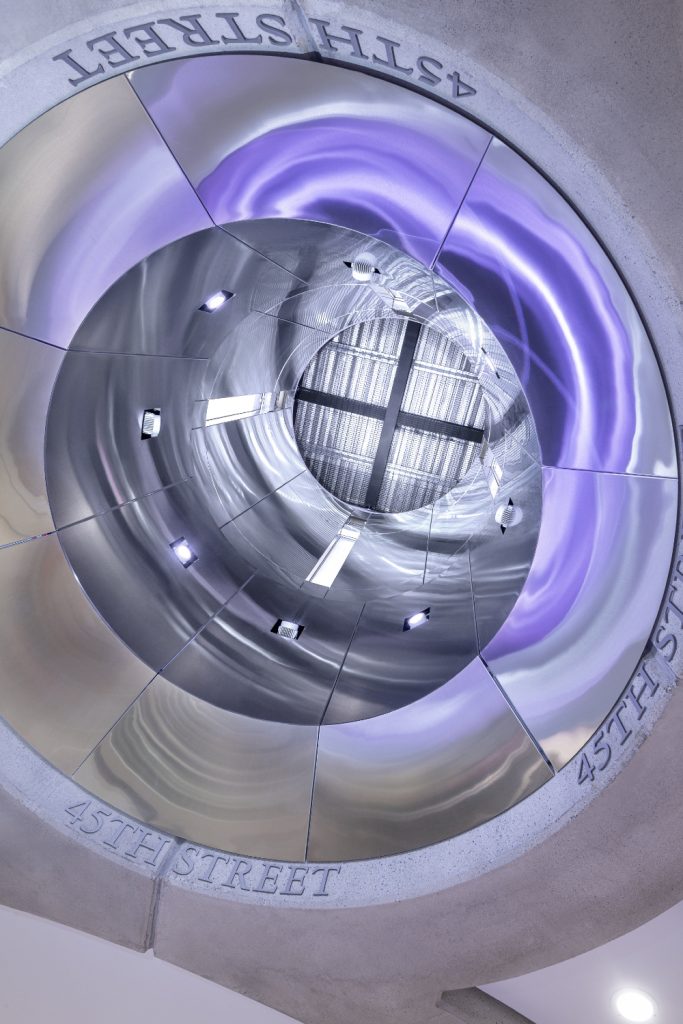

Custom Interior Cladding

Custom Interior Cladding

Versatile Designs that Stand the Test of Time

Custom designs and finishes from Metalwërks® afford architects and designers with significant design freedom for interior and ceiling applications. Our fabrication expertise coupled with the durability and extended lifespan of metal plate ensures that your projects shine for as long as possible.

Unmatched Durability

Prefinished metal panels from Metalwërks® are highly resilient, resisting impact and abrasions even in high-traffic environments. Compared to field-applied finishes that can show wear and tear more rapidly, prefinished metal plates are a low-maintenance option that retain their beauty for decades.

Solutions for Every Substrate

Metal panels come in a variety of textures, profile forms, and unlimited color choices. The result is desirable aesthetics that can be applied to almost every vertical, sloped, or horizontal surface. This includes installation over uninsulated masonry, structural steel, stud backup, and within curtainwall designs.

Designs That Go Beyond

Virtually any vision can become a reality through the highly customizable nature of prefinished metal plate. Designers and architects can specify limitless options for joint treatments. And it’s all offered at a competitive value to other metal or non-metal cladding materials.

- All

Features and Benefits

- Typically manufactured in solid 0.063-0.125” aluminum and 18-gauge to-11-gauge stainless steel

- Contains no combustible plastic or insulation core materials

- Custom fabricated with no minimum production runs or size limitations.

- Panels have uniform strength with no risk of delamination or combustion due to flammable components

- Optional welded panel corners, ground smooth with no visible seams

- All products are engineered and manufactured in-house

- Highly dent- and puncture-resistant; suitable for high-traffic or abusive environments

- Easily curved, contoured for radii down to 6″

- Post-applied finishing (applied after fabrication) by licensed applicators, producing the highest quality results

- Finish warranties up to 20 years (Consult factory for specific limitations)

- 100% recyclable panels manufactured from aluminum plate containing high post-consumer and industrial content, which can contribute to LEED credits.

- Available in no-VOC powder coat finishes

- Solid aluminum construction accommodates curves, 3D profiles, and difficult transitions without unsightly splices or joints common with composite materials

- Highly versatile due to formability for complex applications

Common Applications

- Walls and ceilings

- Stairwells

- Vestibule and entry portal cladding

- Lobby finishes

- Escalators and people movers

- Column covers

- Tunnels

- Concourses and Passenger terminals

Metal Substrate and Finish Options

ALUMINUM

3003-H14 aluminum alloy-temper

Thickness: 0.063” (1 mm) up to 0.187″ (4.75 mm) options

Finishes: Kynar®, acrylic enamel, baked enamel, architectural TGIC Polyester powder coating, or anodized

STAINLESS STEEL

T304 or T316

Thickness: 18 Gauge (0.050”) – 12 gauge (0.101”) (2.78 mm) options

Finishes: #4, #6, #8, and non-directional satin in smooth or custom embossed patterns

Panel Sizes

Widths: 12” (305 mm) to 54” (1,371 mm)*

Lengths: 12” (305 mm) to 160” (4,064 mm)*

Depth: 1″- 1.75″ (44.5 mm) minimum

* Maximum panel size depends upon plate material, gauge, finish, and geometryPanel Weight Range

(Dependent upon gauge and geometry)Aluminum: 2.62 – 3.52 lbs/ft2

Stainless Steel: 2.25 – 4.6 lbs/ft2

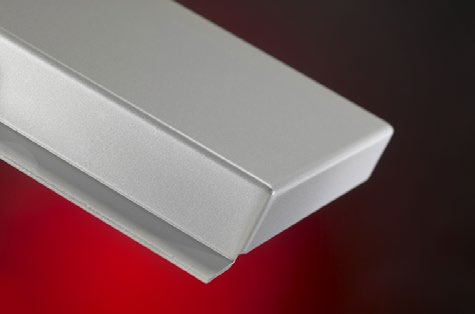

SHARP CORNER

STANDARD CORNER

Accessories

Flashing: 0.040″ (1.016 mm) thick to 0.063″ (1.60 mm) aluminum

Coping: Wall copings may be produced with the same material as the wall panel system

Furring Channels: As required for proper mounting of panels

Fasteners: Type 304 stainless steel or cadmium-plated as recommended

Shims: High impact thermally-broken plastic shims to maintain co-planer surfaces

Warranty

Material & Workmanship: 1-year standard, with 2- or 5-year options

Finish Integrity: 10-year standard and up to 20-year for coated aluminum