- Metalwërks

- Products

Column Covers and Beam Cladding

Product Comparison Chart

Scroll »

| Rainscreen Wall Systems | Barrier Wall Systems | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sculpted 3D* Minimal |

Sculpted 3D* Ribbon |

Sculpted 3D* Parametric |

Arcwall Standard |

Arcwall Advanced |

Arcwall Spline Shiplap |

Econowall | Omniplate 1500 |

Omniplate 2510 |

||

| Performance | Drained and Back-Ventillated Rainscreen |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | × | × |

| AMMA Pressure- Equalized Rainscreen |

× | × | × | × | ✔ | × | × | × | × | |

| Dry-Sealed Barrier Wall |

× | × | × | × | × | × | × | × | ✔ | |

| Wet-Sealed Barrier Wall |

× | × | × | × | × | × | × | ✔ | × | |

| Materials | Coated Aluminum |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Stainless Steel |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Zinc | ✔ | ✔ | ✔ | × | × | × | ✔ | × | × | |

| Panel Forms | Flat | × | × | × | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Curved | × | × | × | ✔ | ✔ | ✔ | × | ✔ | ✔ | |

| 3D | ✔ | ✔ | ✔ | ✔ | ✔ | × | ✔ | ✔ | × | |

| Panel Returns | Formed | ✔ | ✔ | ✔ | ✔ | ✔ | × | ✔ | ✔ | × |

| Flat | × | × | × | × | × | ✔ | × | × | ✔ | |

| Back-Scored | ✔ | ✔ | ✔ | ✔ | ✔ | × | × | ✔ | × | |

| Panel Dimensions (inches) |

Length | 24-160" | 48-160" | 24-160" | 12-160" | 12-160" | 12-240" | 12-160" | 12-160" | 12-240" |

| Width | 24-66" | 24-48" | 24-50" | 12-65" | 12-65" | 12-72" | 6-36" | 12-65" | 12-72" | |

| Depth | Varies | Varies | Varies | 1.75" | 3.75" | 2", 2.25", 2.75" | 1.5" | 1.75" | 2.25" | |

| Panel Orientation | Horizontal | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Vertical | ✔ | × | ✔ | ✔ | × | ✔ | ✔ | ✔ | × | |

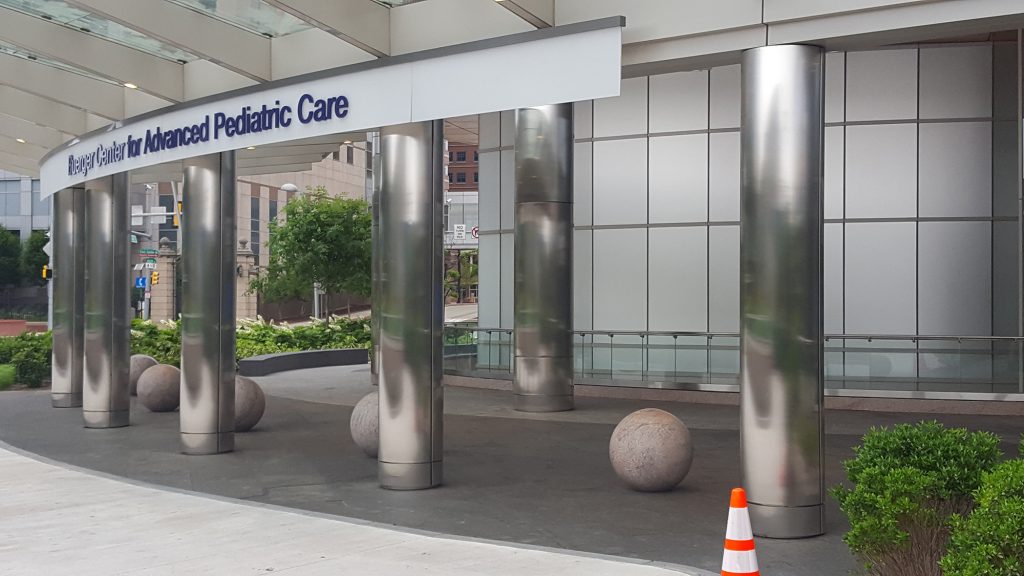

Metalwërks® Column Covers and and Beam Cladding are engineered to provide expanded design flexibility.

Beyond typical cylindrical or square tubular enclosures, Metalwërks Column Covers and Beam Cladding take on virtually any geometrical form as they are manufactured from solid metal plate.

Perfect for enclosing any vertical, sloped, or horizontal structural member – concrete, structural steel, and stud backup – Metalwërks Column Covers and Beam Cladding panels beautifully integrate with Metalwërks plate wall systems.

- All

Features and Benefits of Column Covers and Beam Cladding

Uses of Column Covers and Beam Cladding

- Enclosures for exposed columns, beams, or pilasters

- Custom duct enclosures

- Enhanced interior lobby aesthetics

- Glazed or non-glazed curtain wall applications

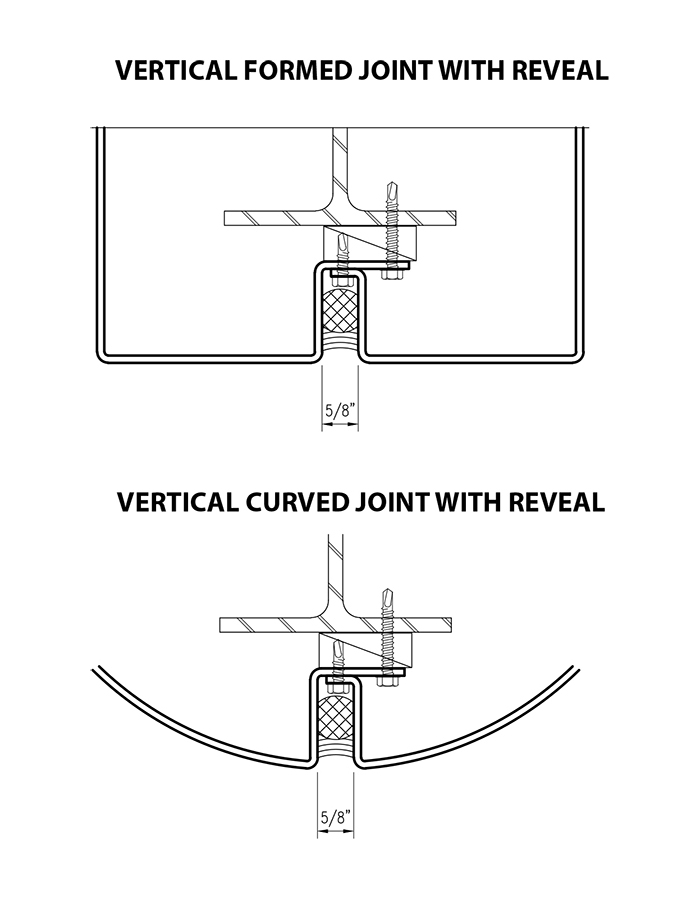

- Available with articulations, reveals and appliqués

- High durability for high traffic areas and transit centers

Metal Substrate and Finish Options

Panel Sizes

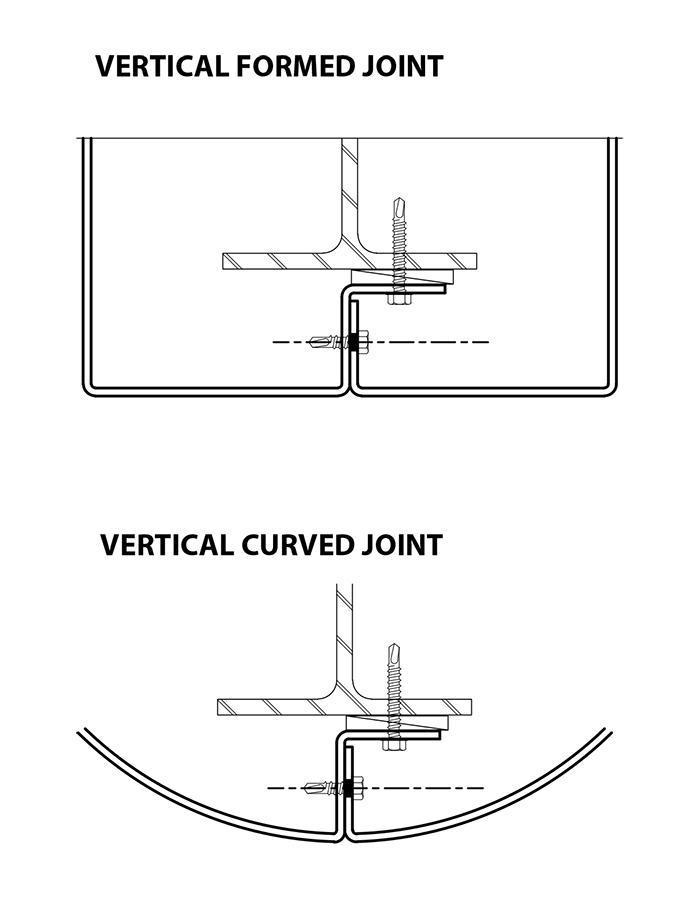

Profiles: Curved and Formed: 12" (305mm) to 66" (1,676mm)*

Lengths: Curved: 12" (305mm) to 192" (4,877mm)*

Formed: 12" (305mm) to 240" (6,096mm)*

Depth: Varies

* Maximum panel size depends upon plate material, gauge, finish, and geometry

Panel Weight Range

(dependent upon gauge and geometry)

Consult with Metalwërks for options.

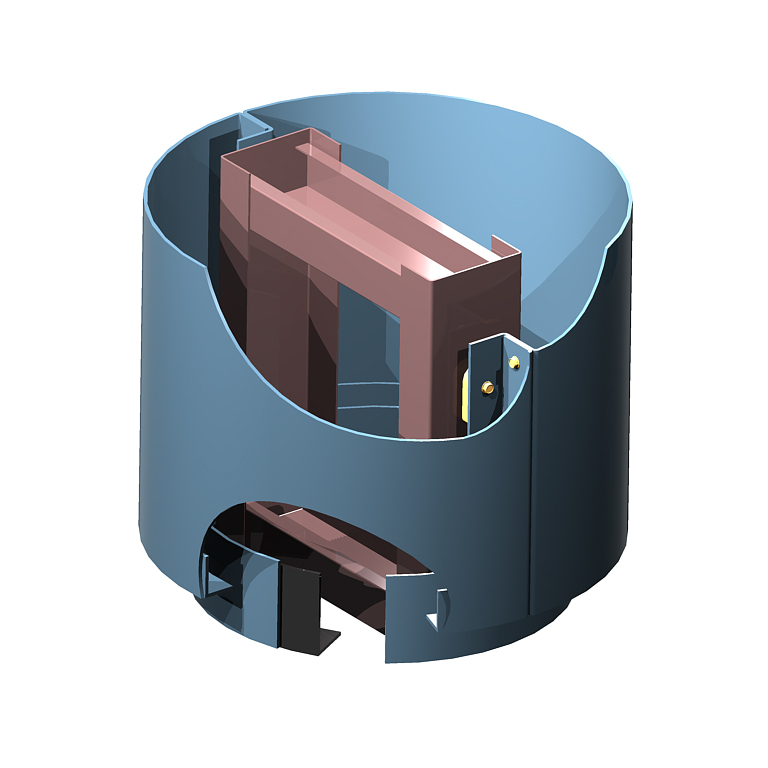

Shapes or Profiles

- Round or square

- Elliptical & racetrack ovals

- Conical or tapered

- Non symmetrical articulations

Accessories

- Support framing

- Articulated capitals and bases

- “Snug fit” spring loaded ceiling closures

- Welded mitered sections, end caps, base reveals beam penetrations

- Access doors

- Sloped base, ceiling terminations

- Curved base, ceiling terminations

- Extruded or formed appliqués

- Accent color reveals

Warranty

Material & Workmanship:1-year standard, with 2- or 5-year option

Finish Integrity: 10-year standard and up to 20-year for coated aluminum