- Metalwërks

Solid Metal Plate: One of Nature’s Most Suitable Exterior Cladding Materials

Solid Metal Plate: One of Nature’s Most Suitable Exterior Cladding Materials

Why Solid Metal Plate is Safer, Stronger, and More Versatile than Alternatives Like ACMs and IMPs

For exterior building facade systems, curtainwall components, and custom architectural features, there are few materials that look and perform like solid metal plate.

Its design possibilities, performance, lightweight composition, strength, infinite finishes, and durability all contribute to exterior facade systems that outperform many others in the marketplace, most notably Aluminum Composite Material (ACM) and Insulated Metal Panels (IMPs). And even with all of its benefits, solid metal plate is cost competitive with these alternatives.

What is Solid Metal Plate?

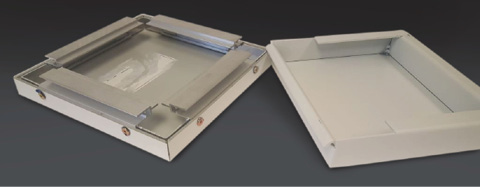

Solid metal plate is a cladding material that offers superior strength and formability. Products and systems produced from this material can be used as architectural features, or as exterior or interior cladding products. To be considered solid metal plate, the metal must be at least 1/8” thick, delivering not only an extremely flat, but durable surface.

The most common substrate metal chosen is aluminum but stainless steel is also popular. When properly designed and engineered for project loads, solid metal plate offers the highest level of long-term performance. Most notably, a reduced risk of damage or denting during installation and the highest degree of durability compared to other sheet metal or composite metal products. Its systems are produced from homogeneous materials, meaning they are never fused with foamed or plastic cores. Therefore, there is no concern for de-lamination or the separation of layers. In addition to its longevity, the amount of maintenance plate requires is very minimal.

Superior Design and Performance

Solid metal plate offers architects the ability to pick and choose from a wide variety of styles and effects for the project at-hand. Dead flat, 3D profiles, and curved designs are all options to capture a plethora of textures and themes. The material is used for wall systems, sunshade integration, canopies, trellises, screenwalls, column and beam covers, and customized enclosures, just to name a few.

To maintain a uniform aesthetic, all of these building features can have the same post-fabrication finishes applied in the same manner. The benefit of applying finish coatings after fabrication is that this alternative method better conceals any welds, polishing, or edges of exposed metal. This gives solid metal plate a distinct advantage over ACM or IMPs, which both require a thin gauge coil coated material as the outer exposed surface bonded to a plastic sheet or plastic foam insulated core.

There are a number of disadvantages of coil coating on ACM and IMPs. While this finishing process is efficient, the material thicknesses that can be coated by this method are limited. Thinner substrates are more prone to damage during fabrication, shipping, installation and during the use of the building. In addition, when panel corners are notched for forming or “rout and return” fabrication, the cuts and notches leave uncoated edges at the most vulnerable locations. And with ACM and IMPs, stiffeners, panel frames, applied reveals, and curved panels must be assembled using a combination of exposed fasteners and adhesives, which can be unsightly.

Solid metal plate systems do not encounter any of these issues. Because they are finished post-fabrication, all curves and appliqués can be welded and ground smooth prior to coating for a seamless appearance, which will not attract dirt or stains. This provides a gem-like quality compared to having exposed screws, seams, or sealants.

Metalwërks also offers its patent pending lighting and irrigated planter options for integrated living wall assemblies — maintaining a closer connection to nature, reducing the heat island effect, and creating a greener atmosphere overall.

Solid metal plate systems offer a completely functional solution for exterior facades. Plate does not absorb moisture, so Metalwërks’ corrosion-resistant systems fight off water damage and keep structures mold-free. Additionally, it holds up against natural forces, airborne debris, or dings and dents commonly found in high-traffic areas. The thickness and single-layer quality of solid metal plate is what gives it superior impact resistance.

No plastics. No foams. Far safer.

With a melting point of over 1200°F1 (aluminum) , solid metal plate is non-combustible2 so fire safety issues are never a concern. There are no plastic or foamed components required, which renders NFPA 285 testing protocols inapplicable. Other metal panel materials like ACM are comprised of either polyethylene or polymeric cores, which will begin to lose their structure sooner, at much lower temperatures. While ACM’s plastic cores pose a significant waste by-product, which is neither biodegradable nor easily recycled once bonded to a metal substrate, solid metal plate contains no toxic or flammable plastic additives, eliminating a health and safety risk in the event of a fire.

True Sustainability

Metalwërks solid metal plate is comprised of recycled content of 3000 or 5000 series Aluminum plate and 6000 series Aluminum extrusions. Solid aluminum plate panels are 100% recyclable after their used life, and in fact, more than 95% of the waste generated during the manufacturing process is also returned into the material stream for recycling. Virtually no materials are sent to landfills. ACM cores and IMP cores are produced from chemical formulations using petroleum based feedstock. Lastly, they require no blowing agents, high-energy processes, high VOCs, or toxic adhesives during assembly — conducive to a safe and environmentally friendly process.

Plate is easily available in increments from 36” to 72” wide coils in 6” or custom increments and can be produced in custom widths to reduce waste. Drop-offs can be utilized and recycled into other components of the product so that most of the raw material is either used or recycled.

Coils for ACM or IMP systems are coated for a particular project and then bonded to a foam or plastic core, often times with custom colors. All of the unused pre-finished materials often end up in landfills because once they are bonded to plastic, they can’t be efficiently recycled. When using solid aluminum plate, all of the left over material can be used on another project, eliminating waste.

These systems easily accommodate renovation and facade rehabilitation projects due to an excellent strength to weight ratio and flexibility of design. Not only do they enhance exterior appearance, but improve the energy performance of older buildings. Solid metal plate systems can be installed with a noncombustible mineral fiber insulation thermal layer, and prepared with cool coatings that are designed to reflect heat. Air-conditioned facilities in warmer climates can especially benefit from this energy-saving measure.

Extremely Cost-Effective

Contrary to popular belief within the industry, solid metal plate is very economical, with a cost comparable to ACM. This is because Metalwërks relies on wellestablished supply-chain relationships, regularly buying plate in large mill quantities or “forward- purchase” contracts depending on project size. The company also invests in forming and production equipment for long-term use and high quality.

Metalwërks solid metal plate systems are particularly cost effective because the company acts as a “one-stop-shop” for their design and manufacturing clients. The company performs all of the materials procurement, finishes and color coordination, design, engineering analysis, construction and fabrication detailing as a part of the product delivery scope. The ability to perform all of these functions in-house enables Metalwërks to confidently and competently provide designers and architects with details and methods that can be trusted, and ensures quality control from start to finish. This level of quality assurance is much less achievable with ACM panels, because most ACM sheet manufacturers are focused on maximizing volume. As a result, they sell their product to third-party fabricators and often times then resell the product to erectors. In fact, ACM panel assemblies are often designed, fabricated and erected by three separate entities. Many ACM fabricators and erectors are competent and expert at their trade, but many are not. With ACM, there are multiple parties in the product custody chain, so assessing liability for a project problem is often impossible.

Solid metal plate can be seamlessly integrated with multiple products — for example, perforated screen wall panels, column covers, and sunshades/trellises — that can all be single-source and post-finished by one manufacturer, ensuring coordination between products and consistent finishing. ACM and IMPs are limited to wall panel applications only.

As for the final product, solid metal plate systems provide a refined visual touch and can achieve the most ambitious designs and meet exacting specifications of designers and fabricators.

The Ultimate Exterior Cladding Material

The characteristics of solid metal plate, in concert with its affordability, make it an ideal choice, and a workable system, for architects looking for design freedom, performance, and functionality all-in-one.

1. John E. Hatch

2. ASM International, Jan 1, 1984

edited by John E. Hatch; Chapter 1 Properties of Pure Aluminum. Page 14-15: