- Metalwërks

- Products

- Rain Screen Wall Systems

Arcwall™

Product Comparison Chart

Scroll »

| Rainscreen Wall Systems | Barrier Wall Systems | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sculpted 3D* Minimal |

Sculpted 3D* Ribbon |

Sculpted 3D* Parametric |

Arcwall Standard |

Arcwall Advanced |

Arcwall Spline Shiplap |

Econowall | Omniplate 1500 |

Omniplate 2510 |

||

| Performance | Drained and Back-Ventillated Rainscreen |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | × | × |

| AMMA Pressure- Equalized Rainscreen |

× | × | × | × | ✔ | × | × | × | × | |

| Dry-Sealed Barrier Wall |

× | × | × | × | × | × | × | × | ✔ | |

| Wet-Sealed Barrier Wall |

× | × | × | × | × | × | × | ✔ | × | |

| Materials | Coated Aluminum |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Stainless Steel |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Zinc | ✔ | ✔ | ✔ | × | × | × | ✔ | × | × | |

| Panel Forms | Flat | × | × | × | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Curved | × | × | × | ✔ | ✔ | ✔ | × | ✔ | ✔ | |

| 3D | ✔ | ✔ | ✔ | ✔ | ✔ | × | ✔ | ✔ | × | |

| Panel Returns | Formed | ✔ | ✔ | ✔ | ✔ | ✔ | × | ✔ | ✔ | × |

| Flat | × | × | × | × | × | ✔ | × | × | ✔ | |

| Back-Scored | ✔ | ✔ | ✔ | ✔ | ✔ | × | × | ✔ | × | |

| Panel Dimensions (inches) |

Length | 24-160" | 48-160" | 24-160" | 12-160" | 12-160" | 12-240" | 12-160" | 12-160" | 12-240" |

| Width | 24-66" | 24-48" | 24-50" | 12-65" | 12-65" | 12-72" | 6-36" | 12-65" | 12-72" | |

| Depth | Varies | Varies | Varies | 1.75" | 3.75" | 2", 2.25", 2.75" | 1.5" | 1.75" | 2.25" | |

| Panel Orientation | Horizontal | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Vertical | ✔ | × | ✔ | ✔ | × | ✔ | ✔ | ✔ | × | |

Arcwall is an economical drained and back-ventilated rainscreen system for both walls and soffits manufactured from formed aluminum or stainless plate.

The system combines excellent performance with a high design flexibility.

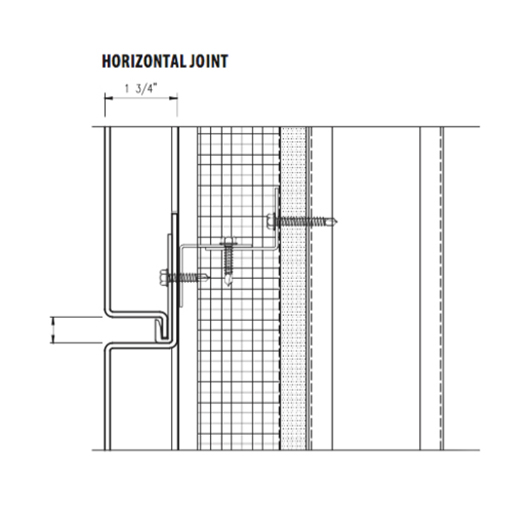

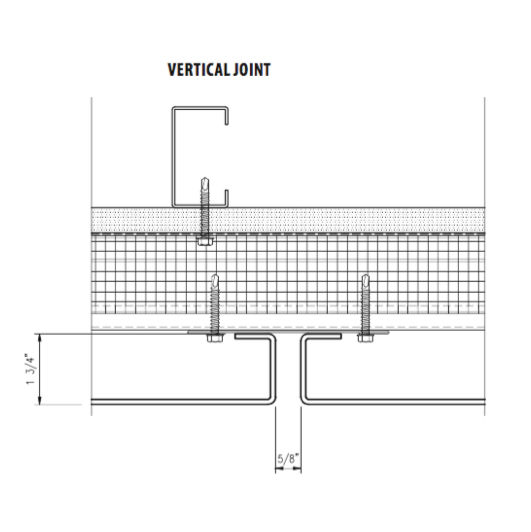

Arcwall panels can be flat, curved, or formed into custom 3D profiles and can be installed both horizontally and vertically. Horizontal reveals are also available in varying heights from 5/8” to 2”.

The system is entirely dry-set with integrally formed interlocking longitudinal joints and simplified backup guttering. This includes formed panels with welded corners and factory-mounted j-hook extrusions for male-female engagement.

Arcwall may be installed over stud/sheathed walls, continuous masonry, concrete, or as the outer cladding in a wall assembly that incorporates continuous insulation and a suitable air and water barrier.

Arcwall Details

Arcwall Design Options

Arcwall Metal Substrate and Finish Options

Panel Sizes

Widths: 12” (305 mm) to 65” (1,651 mm)*

Lengths: 12” (305 mm) to 160” (4,064 mm)*

Depth: 1.75” (44.45 mm) minimum

* Maximum panel size depends upon plate material, gauge, finish, and geometry.

Panel Weight Range

(dependent upon gauge and geometry)

Aluminum: 2.62 - 3.52lbs./ft2

Stainless Steel: 4.64 - 5.913lbs./ft2

Ranges provided for clarification.

Consult with Metalwërks for further options.

Accessories

Flashing: 0.040” (1.02 mm) thick to 0.063” (1.60 mm) aluminum

Coping: Wall copings may be produced with the same material as the wall panel system

Furring Channels: As required for proper mounting of panels

Fasteners: Type 304 stainless steel or cadmium-plated as recommended

Shims: High impact thermally-broken plastic shims to maintain co-planar surfaces

Warranty

Material & Workmanship: 1-year standard, with 2- or 5-year options

Finish Integrity: 10-year standard and up to 20-year for coated aluminum