- Metalwërks

- Products

Omniplate™1500

Product Comparison Chart

Scroll »

| Rainscreen Wall Systems | Barrier Wall Systems | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sculpted 3D* Minimal |

Sculpted 3D* Ribbon |

Sculpted 3D* Parametric |

Arcwall Standard |

Arcwall Advanced |

Arcwall Spline Shiplap |

Econowall | Omniplate 1500 |

Omniplate 2510 |

||

| Performance | Drained and Back-Ventillated Rainscreen |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | × | × |

| AMMA Pressure- Equalized Rainscreen |

× | × | × | × | ✔ | × | × | × | × | |

| Dry-Sealed Barrier Wall |

× | × | × | × | × | × | × | × | ✔ | |

| Wet-Sealed Barrier Wall |

× | × | × | × | × | × | × | ✔ | × | |

| Materials | Coated Aluminum |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Stainless Steel |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Zinc | ✔ | ✔ | ✔ | × | × | × | ✔ | × | × | |

| Panel Forms | Flat | × | × | × | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Curved | × | × | × | ✔ | ✔ | ✔ | × | ✔ | ✔ | |

| 3D | ✔ | ✔ | ✔ | ✔ | ✔ | × | ✔ | ✔ | × | |

| Panel Returns | Formed | ✔ | ✔ | ✔ | ✔ | ✔ | × | ✔ | ✔ | × |

| Flat | × | × | × | × | × | ✔ | × | × | ✔ | |

| Back-Scored | ✔ | ✔ | ✔ | ✔ | ✔ | × | × | ✔ | × | |

| Panel Dimensions (inches) |

Length | 24-160" | 48-160" | 24-160" | 12-160" | 12-160" | 12-240" | 12-160" | 12-160" | 12-240" |

| Width | 24-66" | 24-48" | 24-50" | 12-65" | 12-65" | 12-72" | 6-36" | 12-65" | 12-72" | |

| Depth | Varies | Varies | Varies | 1.75" | 3.75" | 2", 2.25", 2.75" | 1.5" | 1.75" | 2.25" | |

| Panel Orientation | Horizontal | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Vertical | ✔ | × | ✔ | ✔ | × | ✔ | ✔ | ✔ | × | |

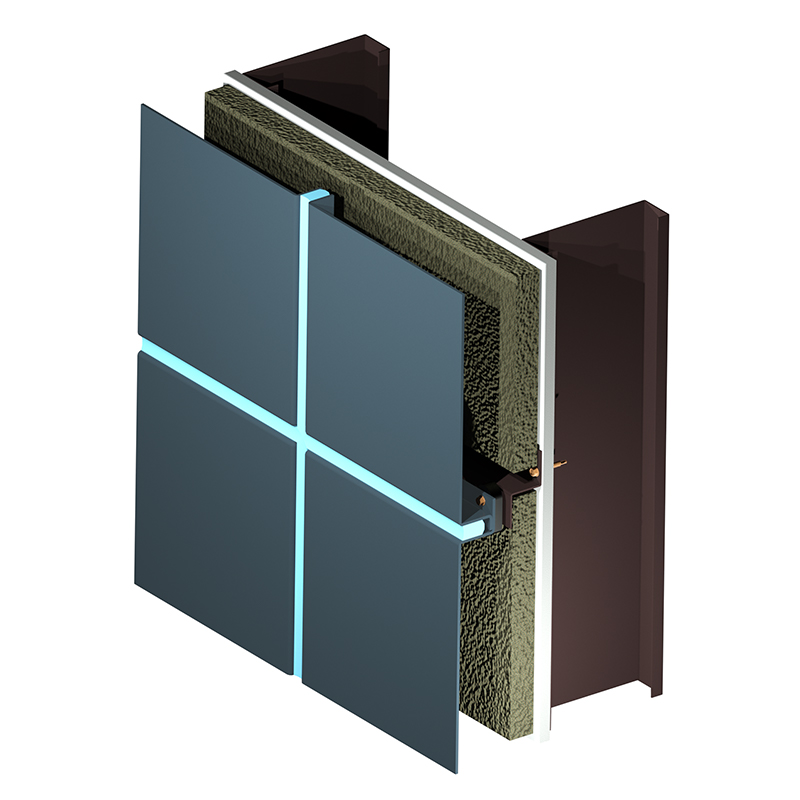

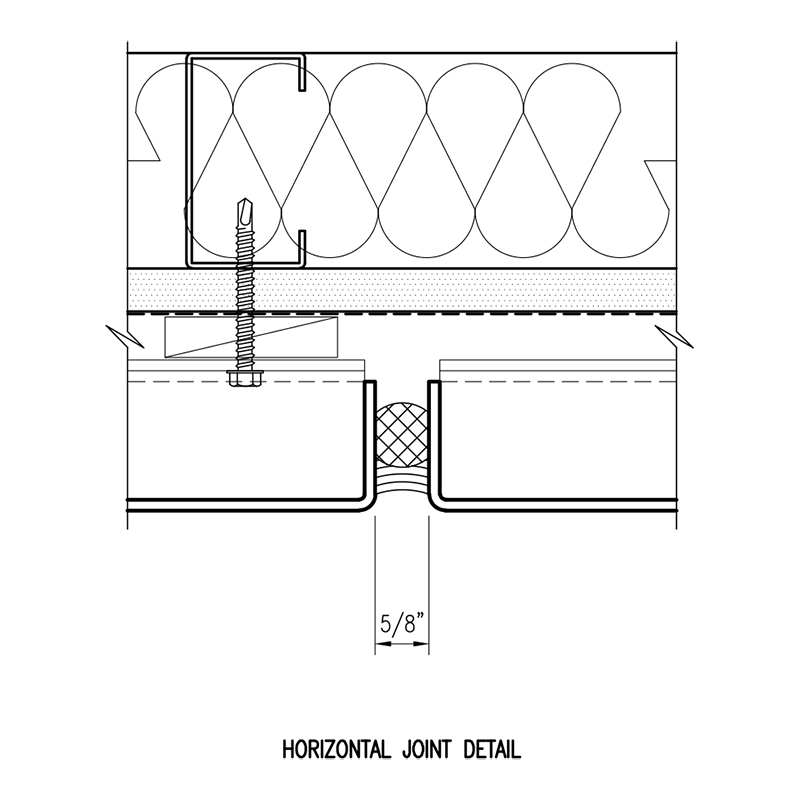

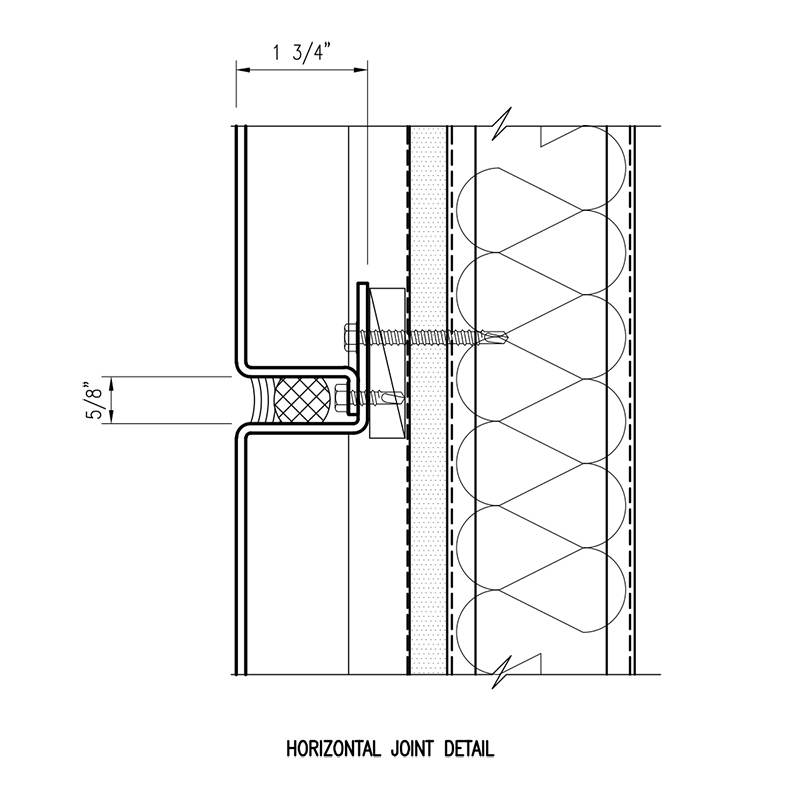

Omniplate 1500 is an economical barrier wall system with visible caulk joints at all horizontal and vertical panel joints.

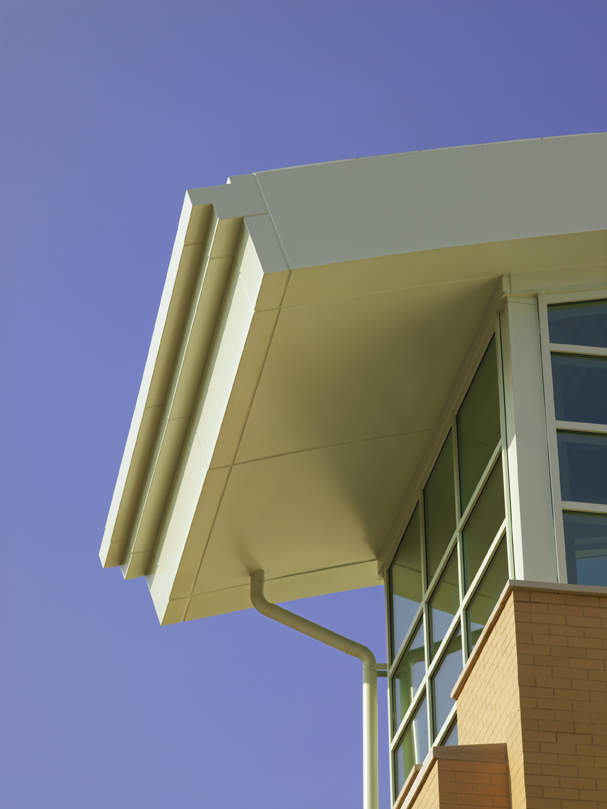

As a barrier wall, Omniplate 1500 serves as the primary weather barrier for the building envelope. It can be installed on vertical, sloped or horizontal surfaces over masonry, structural steel, stud backup or within curtain wall designs.

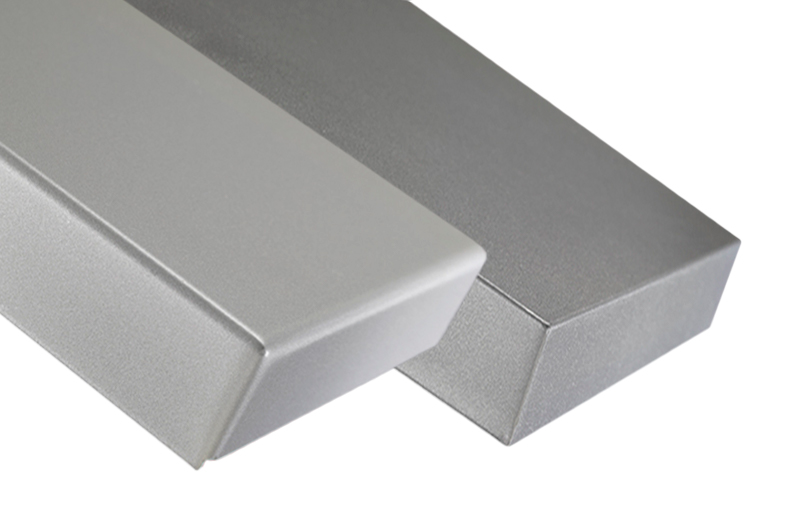

Manufactured from either aluminum or stainless steel plate, Omniplate 1500 provides outstanding freedom of form including curves and complex 3D profiles, and permits challenging transitions without exposed trim or joints.

The system installs with concealed fasteners over studs and continuous sheathing, continuous masonry, or concrete. In addition to walls, the system is suited for vestibules, canopies and eyebrows, as well as for enclosing exposed columns, beams, and pilasters.

Omniplate 1500 Details

Omniplate 1500 Design Options

Omniplate 1500 Metal Substrate and Finish Options

Panel Sizes

Widths: 12” (305 mm) to 65” (1,651 mm)*

Lengths: 12” (305 mm) to 160” (4,064 mm)*

Depth: 1.75” (44.45 mm) minimum

* Maximum panel size depends upon plate material, gauge, finish, and geometry.

Panel Weight Range

(dependent upon gauge and geometry)

Aluminum: 2.22 - 4.02 lbs./ft2

Stainless Steel: 4.64 - 5.913 lbs./ft2

Zinc: Consult with Metalwërks

Ranges provided for clarification.

Consult with Metalwërks for further options.

Accessories

Flashing: Formed sheet metal flashing which may be required at base or penetration conditions produced in the same material finish as the panel system

Coping: May be produced with the same material as the wall panel system

Furring Channels: As required for proper mounting of panels in 16 gauge minimum thickness.

Fasteners: Type 304 Stainless Steel or Cadmium plated as recommended for specific application

Shims: High impact thermally-broken shims to maintain co-planar surfaces

Testing

Air Infiltration: When tested in accordance with ASTM E 283-04

Water Infiltration: No water infiltration shall occur when tested in accordance with ASTM E 331-00 and AAMA 501.1-05 (Static and Dynamic Pressure Water Resistance)

Structural: When tested in accordance with ASTM E330-02

ASTM B 209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Steel

AAMA 2605.2: Voluntary Specification for High Performance Organic Coatings on Architectural Aluminum Extrusions and Panel

Warranty

Material & Workmanship: 1-year standard, with 2- or 5-year options

Finish Integrity: 10-year standard and up to 20-year for coated aluminum