- Metalwërks

- Products

Omniplate™ 2510

Product Comparison Chart

Scroll »

| Rainscreen Wall Systems | Barrier Wall Systems | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sculpted 3D* Minimal |

Sculpted 3D* Ribbon |

Sculpted 3D* Parametric |

Arcwall Standard |

Arcwall Advanced |

Arcwall Spline Shiplap |

Econowall | Omniplate 1500 |

Omniplate 2510 |

||

| Performance | Drained and Back-Ventillated Rainscreen |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | × | × |

| AMMA Pressure- Equalized Rainscreen |

× | × | × | × | ✔ | × | × | × | × | |

| Dry-Sealed Barrier Wall |

× | × | × | × | × | × | × | × | ✔ | |

| Wet-Sealed Barrier Wall |

× | × | × | × | × | × | × | ✔ | × | |

| Materials | Coated Aluminum |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Stainless Steel |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Zinc | ✔ | ✔ | ✔ | × | × | × | ✔ | × | × | |

| Panel Forms | Flat | × | × | × | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Curved | × | × | × | ✔ | ✔ | ✔ | × | ✔ | ✔ | |

| 3D | ✔ | ✔ | ✔ | ✔ | ✔ | × | ✔ | ✔ | × | |

| Panel Returns | Formed | ✔ | ✔ | ✔ | ✔ | ✔ | × | ✔ | ✔ | × |

| Flat | × | × | × | × | × | ✔ | × | × | ✔ | |

| Back-Scored | ✔ | ✔ | ✔ | ✔ | ✔ | × | × | ✔ | × | |

| Panel Dimensions (inches) |

Length | 24-160" | 48-160" | 24-160" | 12-160" | 12-160" | 12-240" | 12-160" | 12-160" | 12-240" |

| Width | 24-66" | 24-48" | 24-50" | 12-65" | 12-65" | 12-72" | 6-36" | 12-65" | 12-72" | |

| Depth | Varies | Varies | Varies | 1.75" | 3.75" | 2", 2.25", 2.75" | 1.5" | 1.75" | 2.25" | |

| Panel Orientation | Horizontal | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Vertical | ✔ | × | ✔ | ✔ | × | ✔ | ✔ | ✔ | × | |

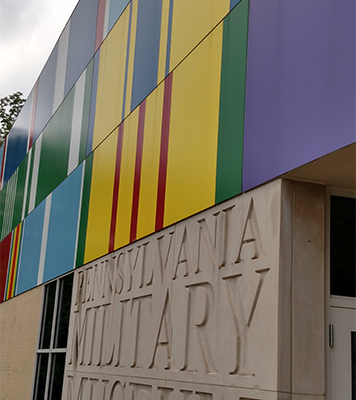

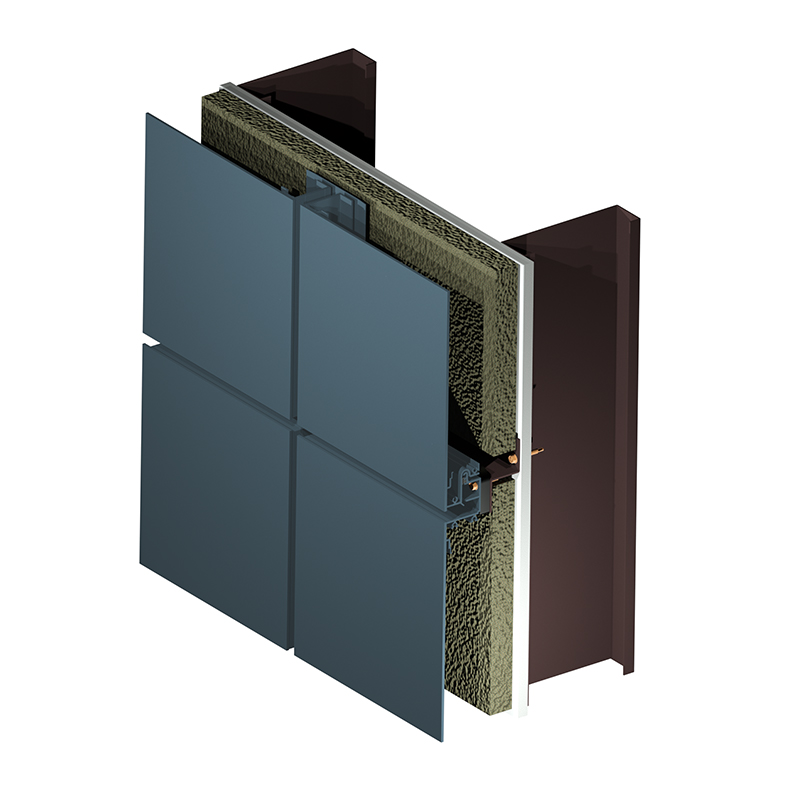

Omniplate 2510 is a premium dry-sealed barrier wall system with panel faces made from solid metal plate with no exposed sealants or gaskets.

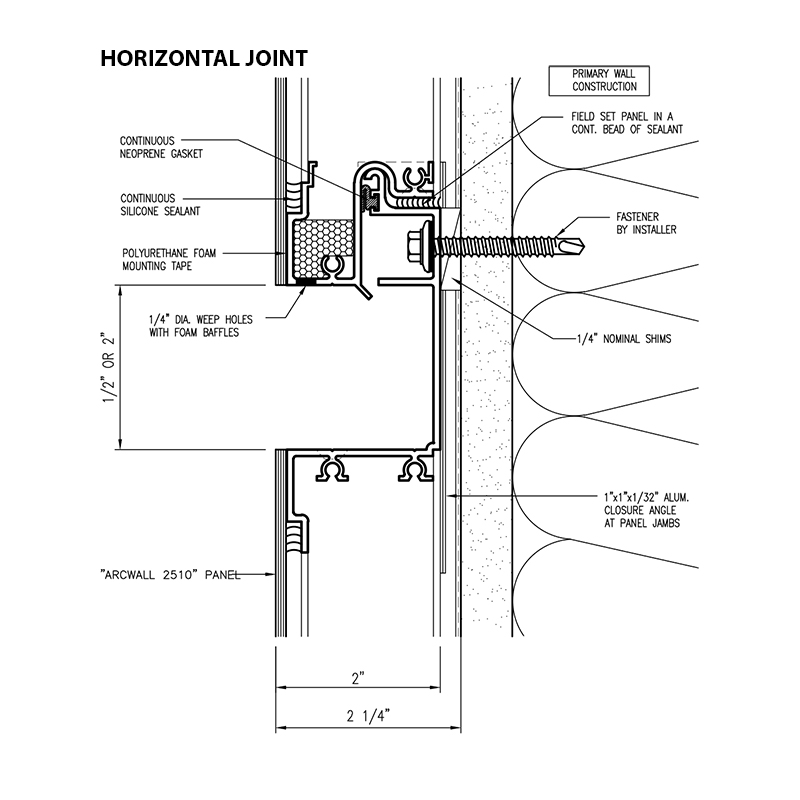

These plate faces are structurally attached to extruded aluminum perimeter framing comprising the panels’ interlocking horizontal joinery. Best suited for horizontally oriented wall design, the vertical gutters capture the drainage from the horizontal joints and shed water to exterior base.

2510 is ideal for flat or curved walls and soffits where the design intent is for pronounced reveals between the panel units and extremely sharp panel edges. Panel frame is exposed as a design element with a deep reveal in matching or contrasting colors.

The system installs with concealed fasteners over studs and continuous sheathing, continuous masonry, or concrete. The panel frame is extremely stiff due to the interlocking components of the assembly, and tested to high wind loads.

Omniplate 2510 Details

Omniplate 2510 Design Options

Omniplate 2510 Metal Substrate and Finish Options

Panel Sizes

Widths: 12” (305 mm) to 72” (1,829 mm)*

Lengths: 12” (305 mm) to 240” (6,096 mm)*

Depth: 2.25” (57.15 mm)

* Maximum panel size depends upon plate material, gauge, finish, and geometry.

Panel Weight Range

(dependent upon gauge and geometry)

Aluminum: 2.22 - 4.42 lbs./ft2

Stainless Steel: 6.32 lbs./ft2

Zinc: Consult with Metalwërks

Ranges provided for clarification.

Consult with Metalwërks for further options.

Accessories

Flashing: Formed aluminum or stainless steel sheet metal flashing which may be required at base or penetration conditions produced in the same material finish as the panel system.

Coping: Wall copings may be produced with the same material as the wall panel system unless otherwise noted.

Furring Channels: As required for proper mounting of panels in 16 ga. minimum thickness.

Perforated Panels or Louvered Vents: For accents, screening or ventilation. Consult with Metalwërks for options.

Fasteners: Type 304 Stainless Steel or Cadmium plated as recommended for specific application

Shims: High impact thermally-broken plastic shims to maintain co-planar surfaces

Testing

Air Infiltration: When tested in accordance with ASTM E 283-04

Water Infiltration: No water infiltration shall occur when tested in accordance with ASTM E 331-00 and AAMA 501.1-05 (Static and Dynamic Pressure Water Resistance)

Structural: When tested in accordance with ASTM E330-02

AAMA 2605-13: Voluntary Specification, Performance Requirements and Test Procedures for Superior Performing Organic Coatings on Aluminum Extrusions and Panels

Warranty

Material & Workmanship: 1-year standard, with 2- or 5-year options

Finish Integrity: 10-year standard and up to 20-year for coated aluminum